QUANTIZ® is a surface analysis system optimized for the evaluation of coating Damage.

It is a combination of hard- and software for image acquisition and evaluation. There is no additional programming required. All analyzes are evaluated according to the respective standards. The operation is optimized with regard to the typical tests (delamination at the scribe, filiform corrosion, multi-chip test, blistering, delamination at the edge, flange corrosion, ...)

» Evaluation options

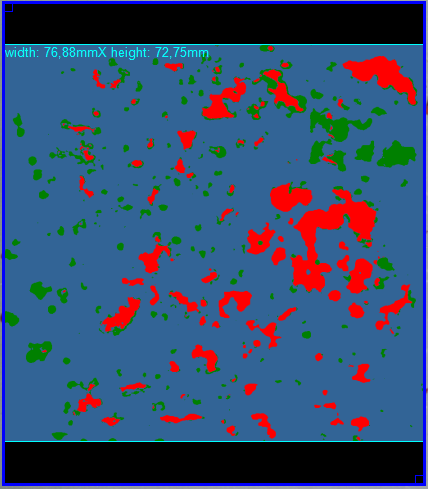

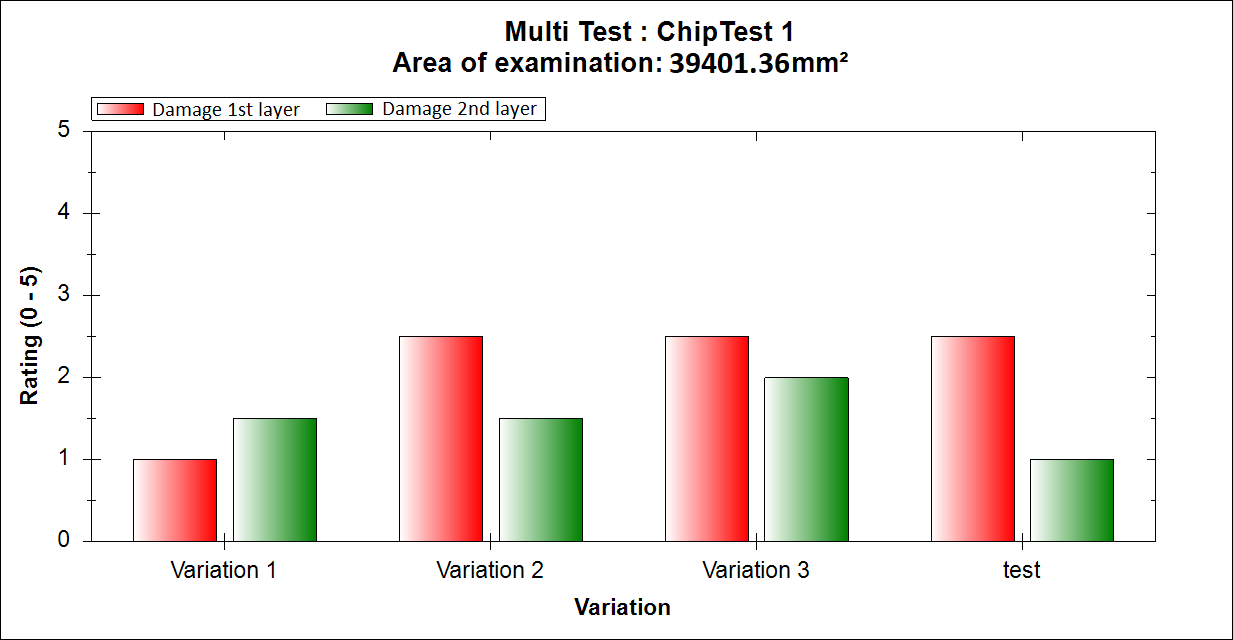

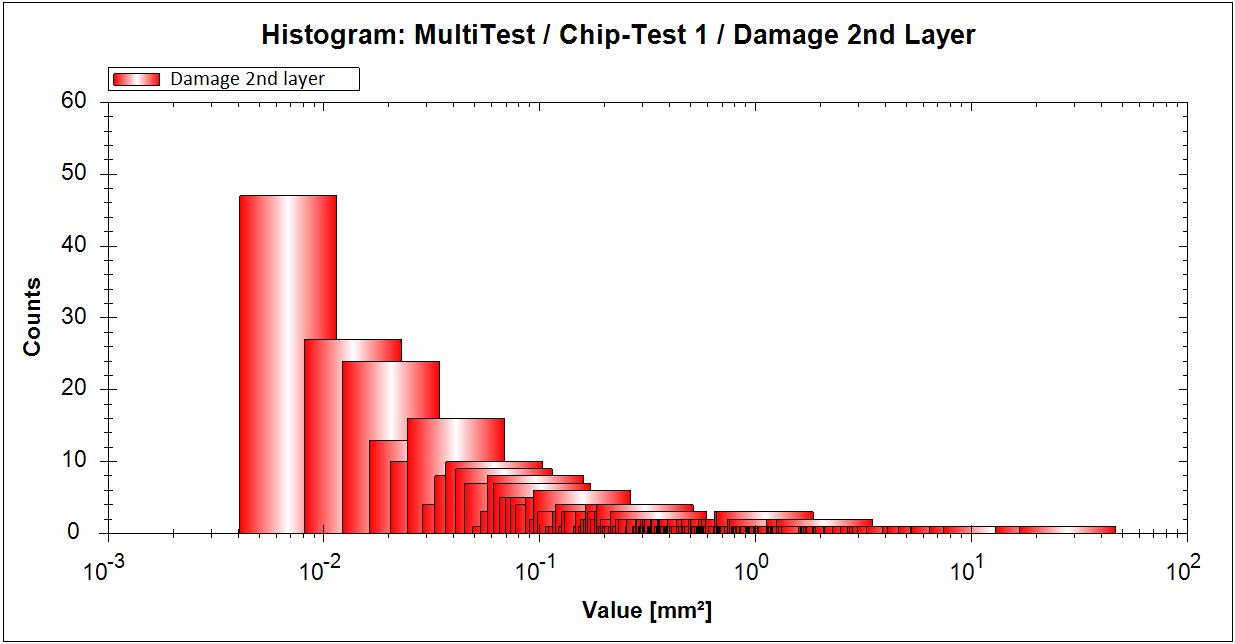

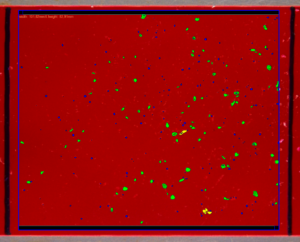

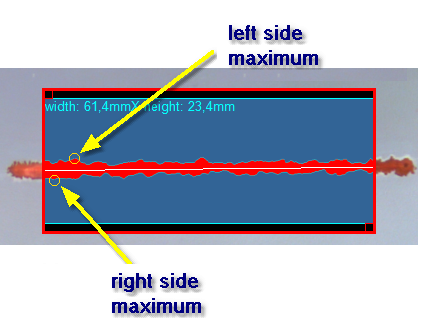

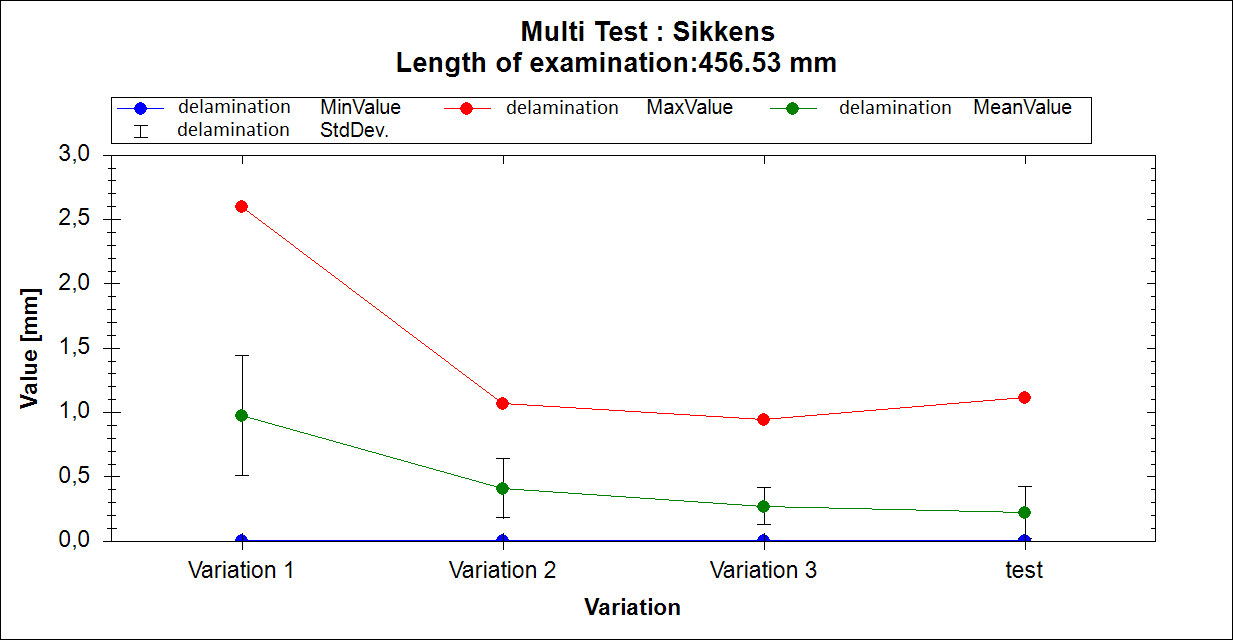

Multi chip test ISO 20567-1, EN ISO 21227-1, EN ISO 21227-2

Multi chip test SAE J400

|

|

Delamination at scribe EN ISO 4628-8 , EN ISO 21227-1, EN ISO 21227-3

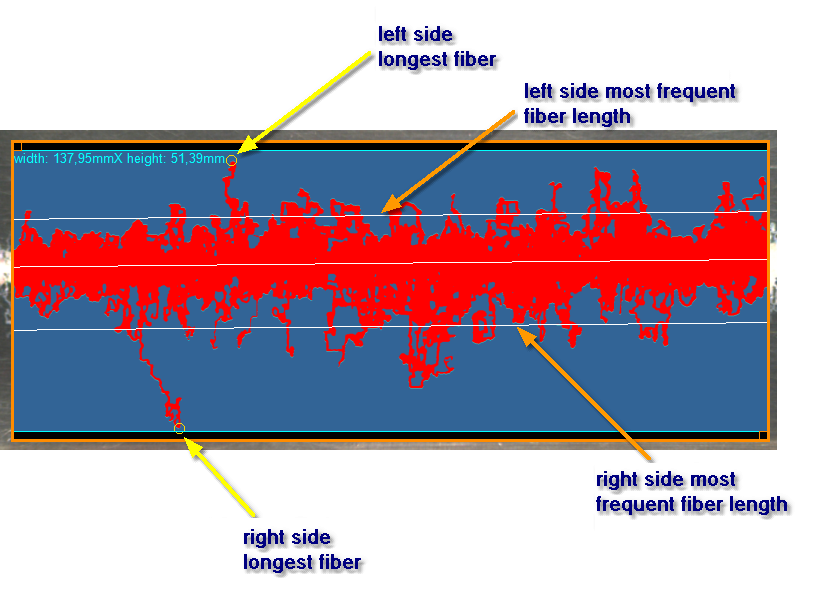

Filiform Corrosion EN ISO 4628-10 , EN ISO 21227-1, EN ISO 21227-4

Determined values:

- Longest fiber left / right / averaged

- Most frequent fiber length left / right / averaged

- Medium filiform width

- Fracturing

- Histogram of fibers

- Characteristic according to ISO 4628-1 (for example L5 / M3: longest thread 5mm, most common thread length 3mm)

- Note: The Quantiz capture unit has brightfield illumination for nondestructive evaluation of filiform corrosion

Blistering EN ISO 4628-2, EN ISO 21227-1

Determined values:

- Medium bubble size

- Smallest, biggest bubble

- Area fraction of bubbles [%]

- Histogram of the bubbles

- Characteristic according to ISO 4628-2 (for example: 2 (S3) bubbles of quantity 2 and size 3)

- Note: The Quantiz acquisition unit has brightfield illumination for nondestructive evaluation of blistering

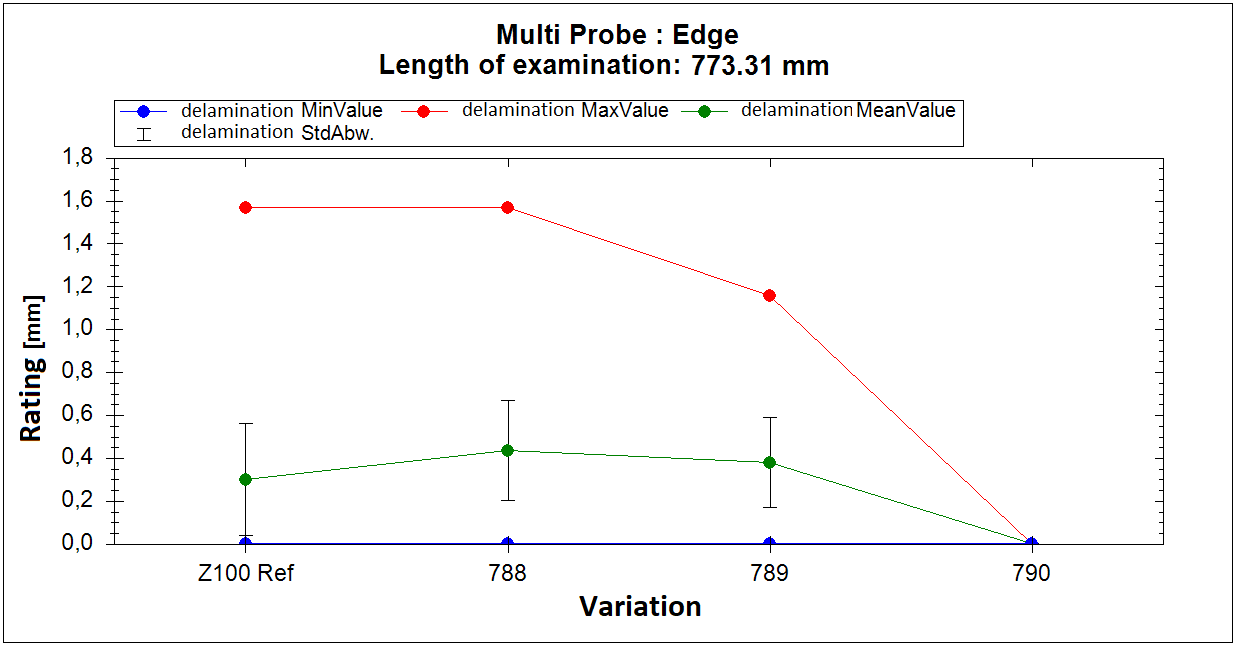

Delamination at the edge EN ISO 21227-1

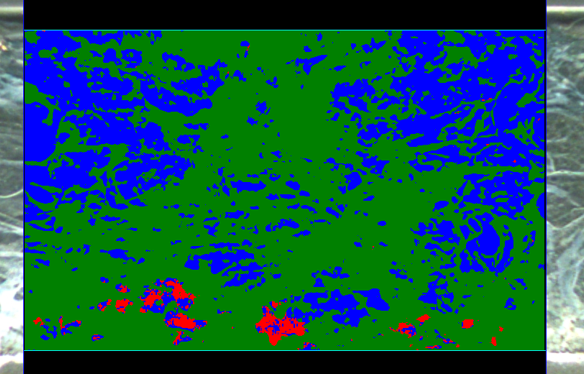

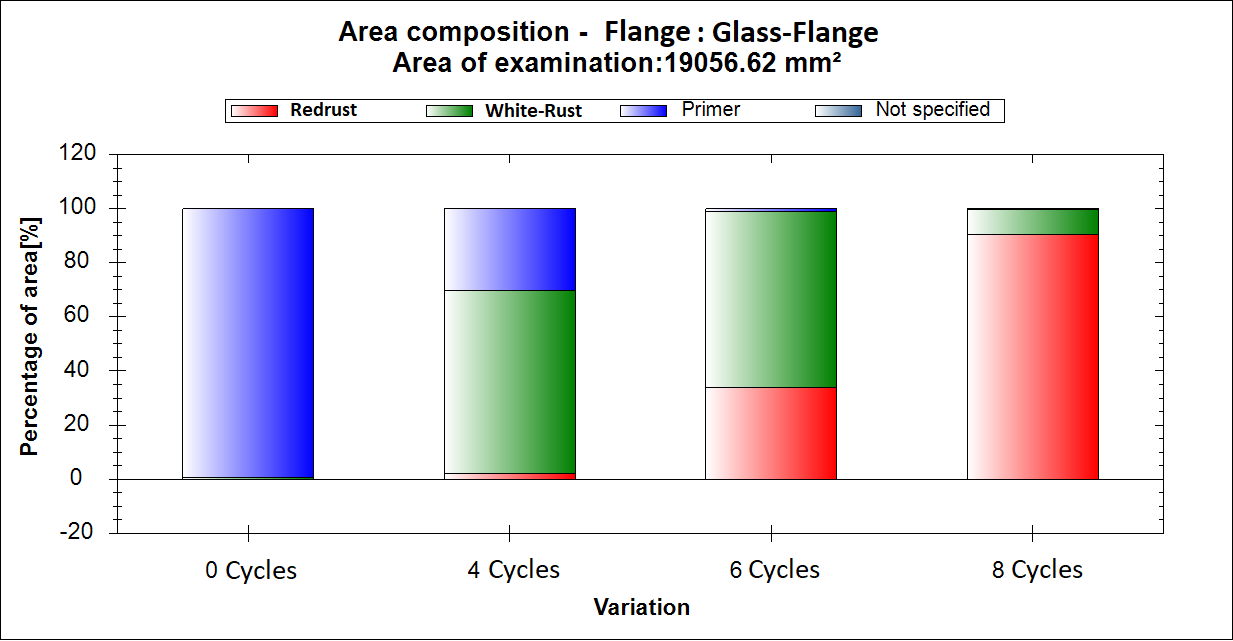

General evaluation of surfaces EN ISO 21227-1

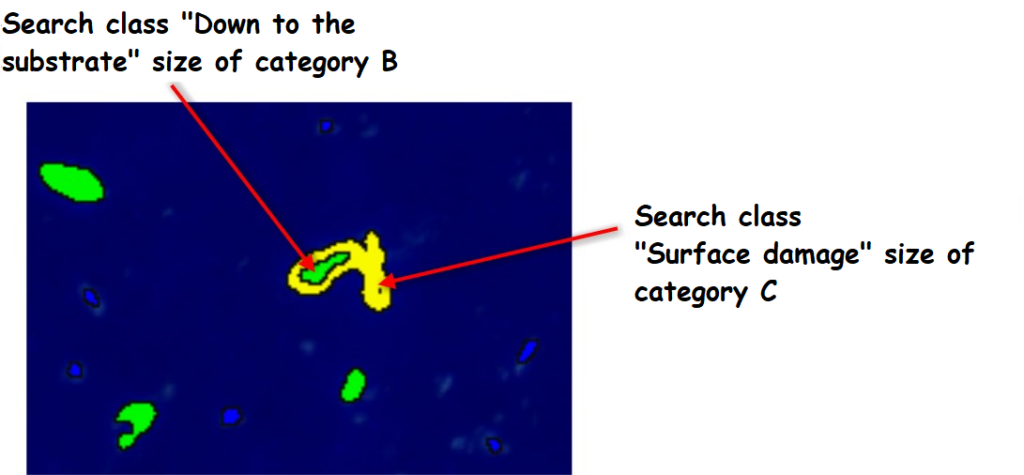

Further possibilities for the image analytic evaluation of surfaces based on EN ISO 21227-1

- Evaluation of the degree of cracking EN ISO 4628-4

- Evaluation of the degree of flaking EN ISO 4628-5

- Cross cut test EN ISO 2409